Corrosion resistant and Refractory bricks experts

Manufacturing, installation, inspection, maintenance and repair of heat, fire and corrosion resistant equipment.

Your rotary kiln and industrial boiler are in good hands

Atwill-Morin‘s experience in masonry maintenance, concrete repair and industrial scaffolding installation is available to any industry that uses a refractory furnace (industrial induction or rotary kiln, hardening furnace) or an industrial or commercial utility boiler. With decades of experience in the field, Gilles Renaud leads our specialized team.

Industrial refractory furnace

Refractory boiler

Anti‑corrosion tank

The experts team dedicated to keeping your corrosion protection and refractory equipment running at optimal levels.

- Rotary kilns and industrial boilers design and installation

- Efficient and safe scheduled maintenance shutdown management

- Acid resistant and refractory bricks repair and replacement

- Ceramic fiber thermal insulation and refractory brick installation

- Carbon fiber concrete reinforcement and refractory concrete repair

- Corrosion inhibition coating membrane installation

- Industrial rotary kilns, boilers, silos, pipes and modular systems repair and maintenance

- Preliminary inspections, annual budgets and maintenance plans for industrial facilities

The experts team dedicated to keeping your corrosion protection and refractory equipment running at optimal levels.

- Rotary kilns and industrial boilers design and installation

- Efficient and safe scheduled maintenance shutdown management

- Acid resistant and refractory bricks repair and replacement

- Ceramic fiber thermal insulation and refractory brick installation

- Carbon fiber concrete reinforcement and refractory concrete repair

- Corrosion inhibition coating membrane installation

- Industrial rotary kilns, boilers, silos, pipes and modular systems repair and maintenance

- Preliminary inspections, annual budgets and maintenance plans for industrial facilities

Scheduled maintenance shutdowns

Plan fast and efficient maintenance of your refractory equipment to ensure the safety of your workers and the continuation of your operations. In collaboration with the other trades involved, we'll plan a complete shutdown of your equipment to ensure that you can quickly resume production. Rest assured that our experts will always meet your deadlines: with crews working night and day, as necessary, to ensure that your maintenance work is completed on schedule.

Pre-repair inspection

All repairs must be preceded by a detailed inspection by our specialists. We examine the interior of your equipment or industrial furnace to assess the repairs that need to be carried out, by hammering the walls or detecting areas of excessive heat with thermal imaging cameras. We can then prioritize repairs over a pre-determined period of time.

Emergency repairs

When urgent repairs or maintenance is needed, in the case of damaged lining in an industrial boiler, a rotary kiln compromised by a hot spot or a leaking tank, our team is available on call 24/7 to help. Atwill-Morin’s experts act quickly because, if left undiagnosed, these issues can result in extensive damage and extended down time.

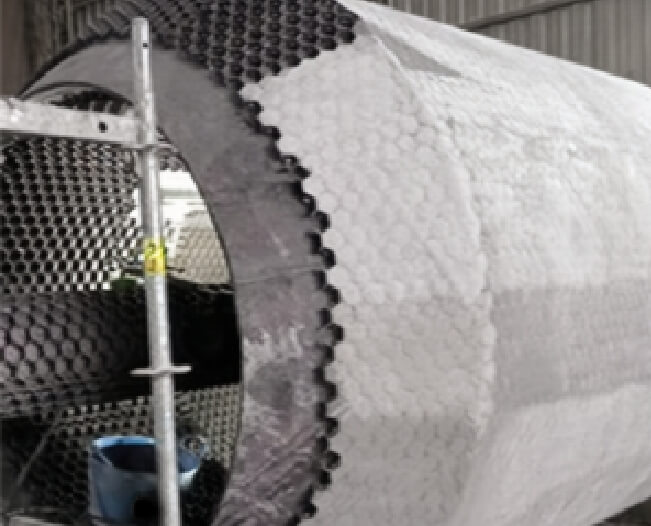

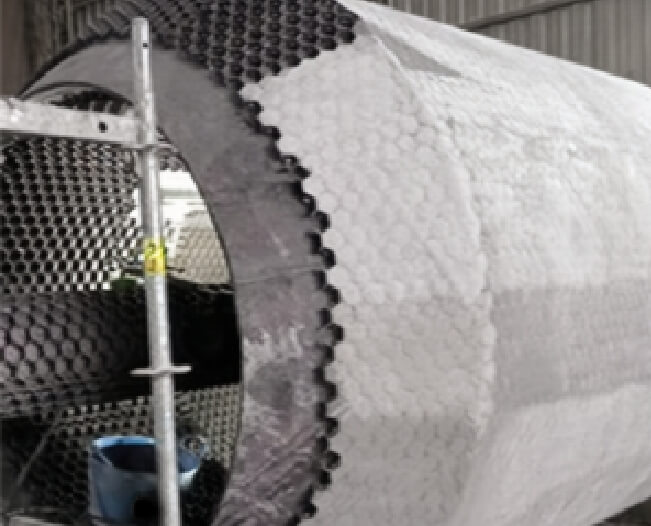

Industrial refractory manufacturing and installation

Entrust us with the complete fabrication of your refractory kiln or corrosion resistant equipment for a sturdy result that will stand up to any industrial use. Depending on your requirements, we can install refractory or anti-corrosion bricks to build your industrial furnace, or apply refractory concrete coatings or membranes to your specialized equipment.

Annual planning and budgets

Over the course of a few weeks, months or years, we can plan and budget for the maintenance and repair of your refractory equipment. With our multi-skilled, qualified staff, we have the expertise to forecast the work that will be required. Let us keep your operation safe!

Structural reinforcement and concrete repairs

Rely on our refractory experts to reinforce the structure of your equipment with carbon fiber and correct weaknesses before breakage or cracks threaten the safety of your workers or the productivity of your business. Reinforcing structures with CFRP increases their load-bearing capacity and resistance to damage. Carbon fiber can be applied to any equipment made of refractory or corrosion-resistant materials.

Our strengths

Workforce availability

A wide range of skilled labor to handle all your refractory needs.

Fast supply

Rapid access to a large volume of refractory and anti-corrosion materials via our numerous suppliers and partners.

Unparalleled expertise

A team with incredible know-how, led by Gilles Renaud, who has logged over 90,000 hours at CCQ in the past 40 years.

Cutting-edge equipment

A wide range of equipment and tooling available, including industrial hammers, chains and thermal imaging cameras.

Across Eastern Canada

Fast, efficient interventions for industries throughout Ontario, Quebec and the Maritimes.

Workforce availability

A wide range of skilled labor to handle all your refractory needs.

Fast supply

Rapid access to a large volume of refractory and anti-corrosion materials via our numerous suppliers and partners.

Unparalleled expertise

A team with incredible know-how, led by Gilles Renaud, who has logged over 90,000 hours at CCQ in the past 40 years.

Cutting-edge equipment

A wide range of equipment and tooling available, including industrial hammers, chains and thermal imaging cameras.

Across Eastern Canada

Fast, efficient interventions for industries throughout Ontario, Quebec and the Maritimes.

Industry-recognized refractory experience

Our director, Gilles Renaud, is accomplished in the field. His know-how and experience are invaluable to our customers. Supported by Sébastien Delli Colli, President of Atwill-Morin refractory, he leads his team of foremen, project managers, specialists and team leaders, with whom our 400 masons and 160 cement applicators work every day.

Industry-recognized refractory experience

Our director, Gilles Renaud, is accomplished in the field. His know-how and experience are invaluable to our customers. Supported by Sébastien Delli Colli, President of Atwill-Morin refractory, he leads his team of foremen, project managers, specialists and team leaders, with whom our 400 masons and 160 cement applicators work every day.

For refractories on the largest industrial sites

Paper mills, sawmills, foundries, cement plants and other petrochemical organizations can count on Atwill-Morin’s specialized, fast and safe service, backed by reliable supply partners, state-of-the-art equipment and all the necessary certifications for their refractory and anti-corrosion equipment.

Pulp and paper industry

Metal and minerals industry

Chemical and petrochemical industry

Energy and electricity industry

Contact us

Our relationships are built on trust, hard work, and our reputation for excellence.

FAQ for your refractory and corrosion-resistant equipment

What are the main tools and equipment used in refractory manufacturing and maintenance?

At Atwill Morin, we use state-of-the-art equipment: we use thermal and infrared cameras to detect areas that are generating too much heat. To maintain and repair concrete, we use Gunite or shotcrete pumps, as well as mortar mixers. Our inventory also includes radial brick and block saws, and remote-controlled hydraulic hammers (Brokk).

Tips for choosing the right supplier for refractory installation and repair

The workforce has to be experienced in health and safety, as well as in large-scale projects. Teams must be properly trained, as is the case at Atwill Morin, by following training programs and keeping up to date with the latest technologies in refractories and anti-corrosion equipment.

What specific materials are used to reinforce refractories?

We use refractory bricks or alumina shotcrete (Gunite) for heat and fire resistance, and ceramic-like anti-corrosion bricks for equipment that needs to resist corrosion. In terms of refractory bricks, we use a variety such as ultra-dense zircon, burnt magnesia, dense low-porosity and fireclay.

How can we bring your project to life?

We show respect for the jobs entrusted to us by constantly focusing on our ultimate goal: bringing our clients’ ideas and vision to life.