RH Montreal

Montréal

2024

Montréal

2024

Façade and Architectural Elements Masonry

Our masons carried out highly meticulous work on the bricks imported from Italy, which had an exceptionally high absorption rate. Each brick was first soaked in one-thousand-liter water tanks until fully saturated, then dried to reach the optimal moisture level before installation. This process ensured better adhesion with the mortar. At the same time, nearly thirty-five thousand bricks were cut to match the dimensions required by the original design, a meticulous task completed both on site and in our warehouse.

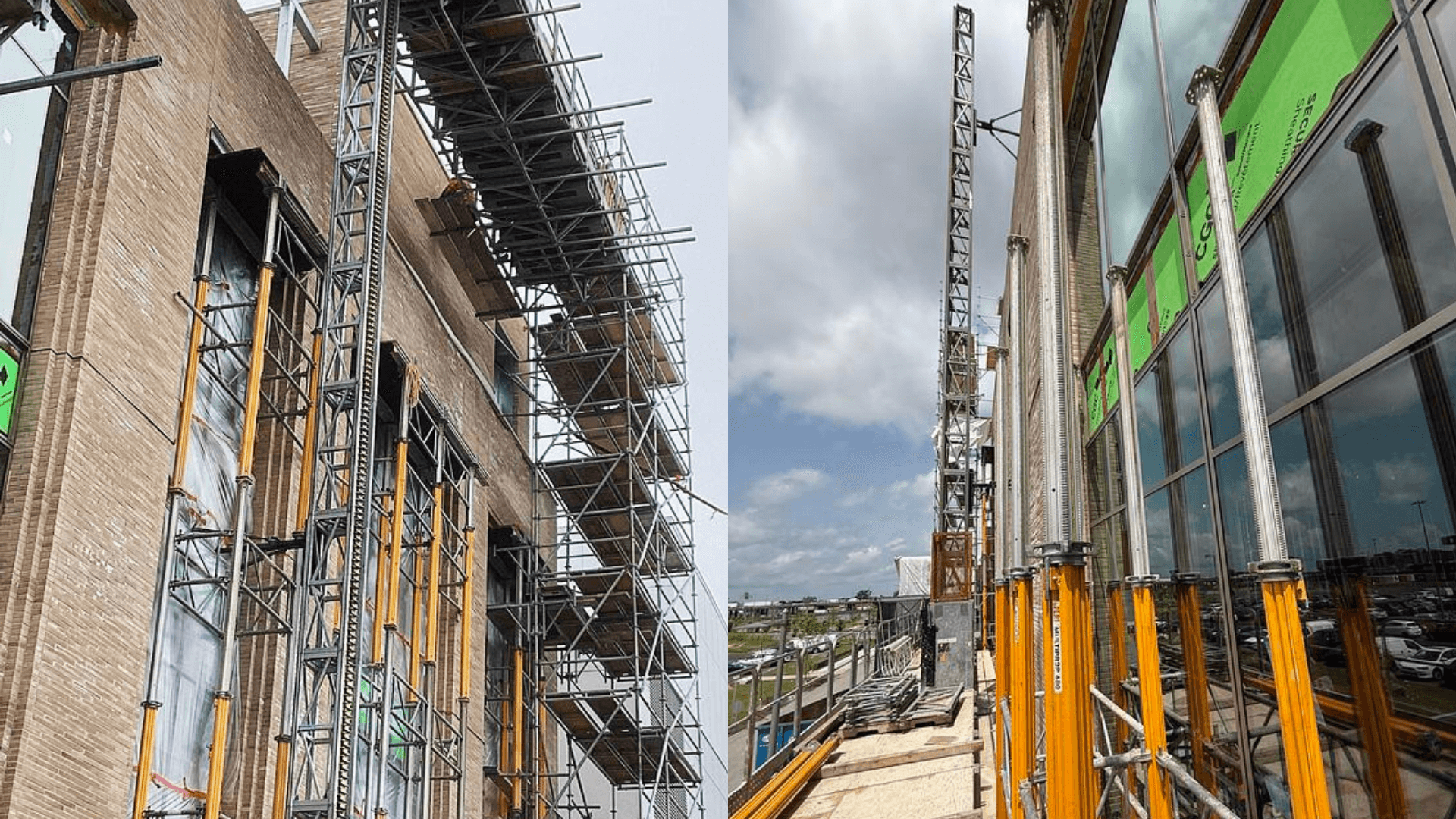

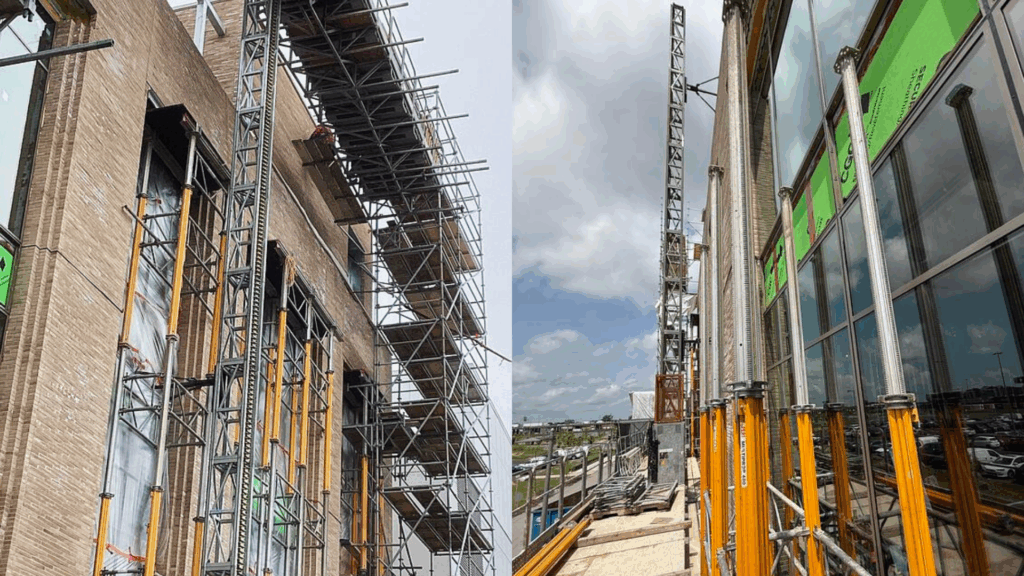

Among the most notable architectural features of RH Montreal, the concealed lintels create the illusion that the brick is floating. These hidden lintels stand out for their ingenuity: the brick was drilled to allow the reinforcement to pass through. The result is a refined and discreet elegance that elevates the entire façade. To achieve this architectural feat, each window was precisely surveyed to ensure perfect alignment during installation. To save time and avoid resurfacing the joints, our team created custom plastic tabs inserted into the joints to keep them empty until the mortar set. This innovation optimized workflow while ensuring the quality of the final result.

A temporary PERI shoring system was developed and designed by our team specifically for this project to support the brick above the window openings during mortar curing. It was an efficient, simple, and economical solution. Once the curing period was completed, the shoring elements were gradually released and removed, freeing the structure without compromising the strength of the masonry.

Maison RH is unlike any other project we’ve done. Notably, our masons installed eight Greek-style columns fabricated in Texas, anchored to the steel structure and assembled by hand inside the boutique. In addition, instead of the standard configuration with two rows of stretchers, a three-row masonry layout was used. Finally, the parapet was built entirely in stone, with no metal coping, using nine different prefabricated stone shapes.

Façade and Architectural Elements Masonry

Our masons carried out highly meticulous work on the bricks imported from Italy, which had an exceptionally high absorption rate. Each brick was first soaked in one-thousand-liter water tanks until fully saturated, then dried to reach the optimal moisture level before installation. This process ensured better adhesion with the mortar. At the same time, nearly thirty-five thousand bricks were cut to match the dimensions required by the original design, a meticulous task completed both on site and in our warehouse.

Among the most notable architectural features of RH Montreal, the concealed lintels create the illusion that the brick is floating. These hidden lintels stand out for their ingenuity: the brick was drilled to allow the reinforcement to pass through. The result is a refined and discreet elegance that elevates the entire façade. To achieve this architectural feat, each window was precisely surveyed to ensure perfect alignment during installation. To save time and avoid resurfacing the joints, our team created custom plastic tabs inserted into the joints to keep them empty until the mortar set. This innovation optimized workflow while ensuring the quality of the final result.

A temporary PERI shoring system was developed and designed by our team specifically for this project to support the brick above the window openings during mortar curing. It was an efficient, simple, and economical solution. Once the curing period was completed, the shoring elements were gradually released and removed, freeing the structure without compromising the strength of the masonry.

Maison RH is unlike any other project we’ve done. Notably, our masons installed eight Greek-style columns fabricated in Texas, anchored to the steel structure and assembled by hand inside the boutique. In addition, instead of the standard configuration with two rows of stretchers, a three-row masonry layout was used. Finally, the parapet was built entirely in stone, with no metal coping, using nine different prefabricated stone shapes.

An Unprecedented Achievement

Join our Winning Team

We provide a rich, open, responsive, and close-knit work environment. As an employer, we foster strong team spirit and treat our people with respect and consideration.

News

Media Appearances

Community Involvement

News about our team, achievements, and community involvement. Our work stands the test of time, and we are constantly striving to become even better.

News

Media Appearances

Community Involvement

News about our team, achievements, and community involvement. Our work stands the test of time, and we are constantly striving to become even better.